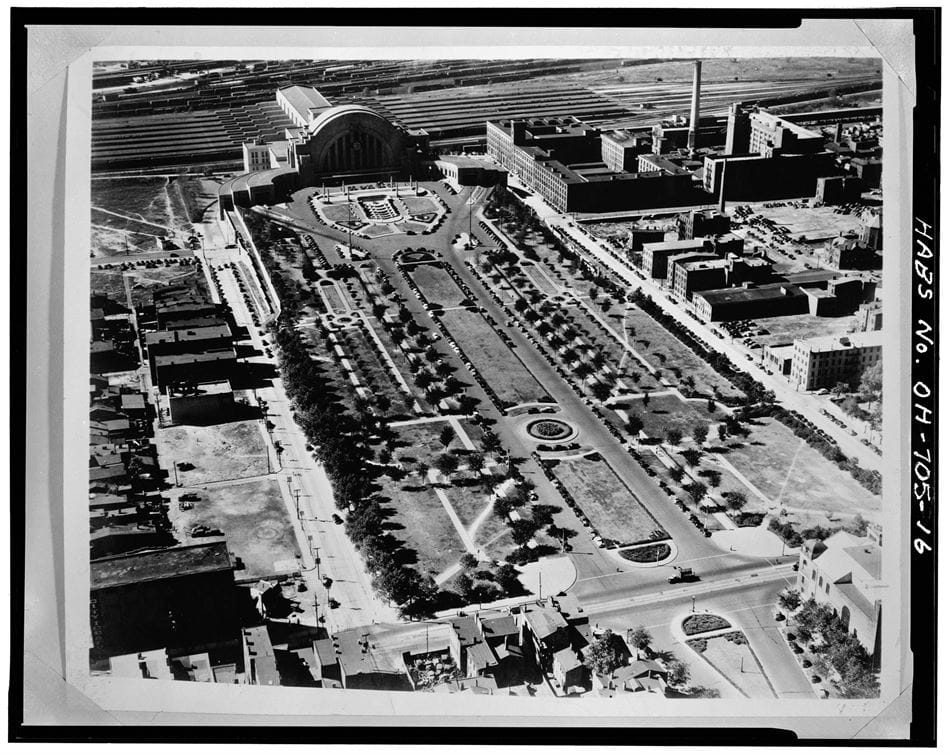

Known as the “Gateway to the West,” the Cincinnati Union Terminal (CUT) was once one of America’s grandest transportation hubs, at one point boasting as many as 20 separate lines and more than 200 daily trains. But in 1972, with the demand for passenger rail in steep decline, the station was shuttered and only narrowly escaped destruction.

The art deco masterpiece, which features sprawling mosaic murals by Winold Reiss and the largest semi-dome in the western hemisphere, lay largely dormant for much of the next two decades until it was gifted to the City and transformed into a museum centre that opened its doors in 1990.

Restoration ramps up

By the 2000s, CUT was acknowledged to be one of the 50 most significant buildings in the US. It was also badly in need of refurbishment. A restoration masterplanning effort was launched in 2007. Arup’s involvement in the project began four years later, in 2011, when we participated in a workshop to address the masterplan’s sustainability. The solutions proposed by workshop participants ultimately helped Cincinnati pass a measure securing the funding needed to restore the building.

The Cincinnati Union Terminal Restoration project officially kicked off in 2015, with Arup selected to provide mechanical, electrical, and plumbing engineering and lighting, AV and acoustics consulting.

The CUT project had two primary objectives: to restore as many elements of the station’s original architecture as possible, and to bring it in line with modern performance and safety standards. The role of our team was to develop building system strategies that capitalized on existing architecture to deliver an overall reduction in energy use. Integrating state-of-the-art building and technology systems in a historically-sensitive manner required holistic problem solving and a high degree of interdisciplinary collaboration— both of which were facilitated by having the project’s MEP, lighting, AV and acoustics specialists located under one roof.

Centralised systems

The replacement of CUT’s emergency system offers one example of the benefits provided by Arup’s holistic, interdisciplinary approach. The station’s existing system, which was located inside the building, hadn’t been upgraded since 1989 and didn’t provide the backup necessary to safeguard museum exhibits and collections. But installing a larger system indoors would have necessitated a major structural renovation precluded by the project’s preservation goals. To get around this problem, our electrical and mechanical engineers decided to locate a large generator outside and worked closely with the architect and contractor to determine the best way to run conduits through the building, with the aid of BIM modeling.

The primary challenge was that the station’s electrical systems were long out-of-date and non-code compliant. Unlike modern electrical systems, they weren’t located in a stacked electrical closet, but diffused throughout the building, making it difficult to determine the amount of the load on each panel. There was also no central lighting control system and building personnel were forced to traverse the 500,000ft2 building to shut things off manually. We developed a centralised lighting scheme to eliminate these problems. We also oversaw the refurbishment of CUT’s historic light fixtures, and used a complementary modern fixture, which could be calibrated to meet a variety of uses, to supplement lighting throughout the building.

Devising an efficient, aesthetically sensitive strategy for routing building system infrastructure throughout a large structure that houses variety of space types was also challenging. CUT lacks the “back of house” areas generally used to route ductwork and piping. This made it necessary for our mechanical engineers to work closely with architects to find innovative ways to weave systems into public spaces, while preserving room heights and architectural elements. For example, all of the mechanical equipment that serves CUT’s train exhibit is located directly outside the space and fed inside in a manner that blends with the mechanical features of the train display. The heating and cooling system incorporates a mechanical chiller and a 4000-ton ice storage yard and provides enough cooling power to completely eliminate the need for mechanical cooling in the spring and winter months.

Taking telecommunications up a notch

One of the project’s most technologically advanced features is its Passive Optical Network. Among the first systems of its scope in the country, this Arup-designed telecommunications network replaces all of the station’s outmoded telecom equipment with a building-wide fiber optic network that supports the data network, Wireless Access Points, and the Cellular Distributed Antenna System (CDAS). This innovative approach minimised structural work, thus protecting CUT’s historic character. To optimize use of the network, we conducted workshops to help the owner develop a technology road map. The workshops led to the implementation of new tech-enabled museum systems, including Wi-Fi tracking, video-audio distribution, and exhibit digital support.

Now renovated to meet the demands of the 21st century, the historic CUT terminal was reopened to the public in the winter of 2018. Despite the incorporation of additional museum exhibits and other new features, the building achieves new levels of resource efficiency, thanks in large part to Arup’s sustainable design strategies.

;

;

.jpg?h=394&mw=700&w=700&hash=2E9858F3036A5F8A0A794F40D9641F5F)