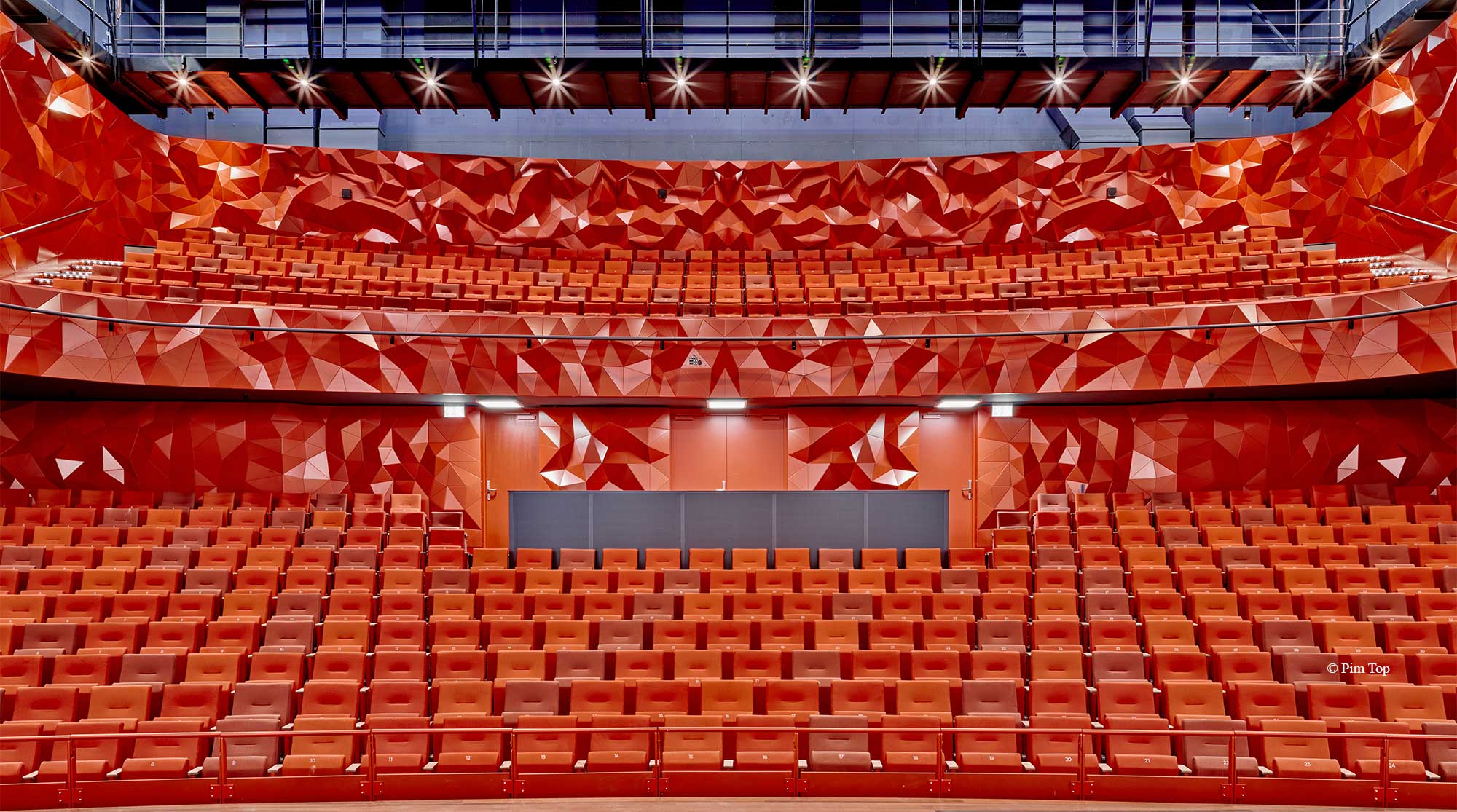

Putting the South neighbourhood firmly back on the city’s cultural map, Rotterdam’s newly open Theater Zuidplein has an ambitious mission: to become a neighbourhood ‘living room’, staging productions addressing society’s most pressing contemporary issues.

At the heart of the new mixed-use building, designed by De Zwarte Hond, lies the new, deep-red auditorium: like an ingenious antique jewel-box, the 600-seat hall can open up to accommodate up to 1,000 standing, dancing guests.

Designed by Rotterdam’s Studio RAP Architects, the auditorium creates a wrap-around, immersive atmosphere for both the audience as well as the performers. Arup provided acoustic and structural engineering services to design the acoustic shell using an algorithm-driven design process.

The striking, enveloping wall features 6,000 unique, folded triangular panels made of aluminium composite - an unexpected choice of material for a theatre hall. Placed at different angles, the acoustic wall also breaks up the light into countless crimson tones, creating a dynamic play of colours and depth in the venue.

Our enhanced parametric digital design tools allowed our engineers to optimise the shape of the theatre shell in order to achieve the desired acoustic performance within a complex design environment. Through this parametric ‘sound-shaping’ process, our engineers ran a series of scenarios to evaluate the impact of the auditorium’s wall design on the acoustics, optimising the final shape of the wall, as well as the pattern and placement of the triangles, at different angles.

Project Summary

6,000 unique acoustic panels

10,000+ design options explored

2,800 unique structural connection elements

The striking design comes to life as an enveloping, bright red acoustic wall made up of 6,000 unique, folded triangular panels. © Pim Top

Parametric tools – optimising the acoustic shell

Arup’s digital tools allowed our engineers to optimise the shape of the acoustic shell. The team defined a series of design variables, optimisation objectives and constraints, from the geometrical boundaries of the hall to the positioning of the sound sources, to help refine the design.

Through a parametric ‘sound-shaping’ process, our engineers then ran a series of scenarios to evaluate the impact of the different wall designs on the hall’s acoustics, and used this to inform and model the final shape of the wall, as well as the pattern and placement of the triangles at different angles.

“Digital tools allow for a very smooth, collaborative workflow with all the stakeholders, allowing us to stay flexible and make all the unique 6,000 panels within time and budget. It was a very unique design from algorithm to reality. ”

Shibo Ren Senior Engineer | Structures Learn more about how digital is shaping our approach to design

Digital workflow enables agile collaboration

Working in close collaboration with all stakeholders, Arup developed a digital workflow that integrates the geometrical complexity, acoustic optimisation, structural logic, and fabrication. Structural rules have also been combined with the digital model to customise the detailing of all the unique panels and their connections. The setup of this digital workflow allowed the team to explore numerous options in quick succession, leading to the final, optimised wall design.

;

;