What we delivered

-

Implementing new methods to overcome the climate emergency through building refurbishments to save time, money and carbon.

-

Transforming 1 Triton Square for today’s workstyles through Arup’s marginal gains approach to deliver a highly sustainable building.

-

Resulting in a healthy workplace with exceptional amenity and social connectivity.

Get in touch with our team

Responsible for 40% of global energy-related carbon emissions, the built environment is a major contributor to climate change. Reducing its impact is vital in overcoming the climate emergency and to make this possible we must find new ways to design and build our cities.

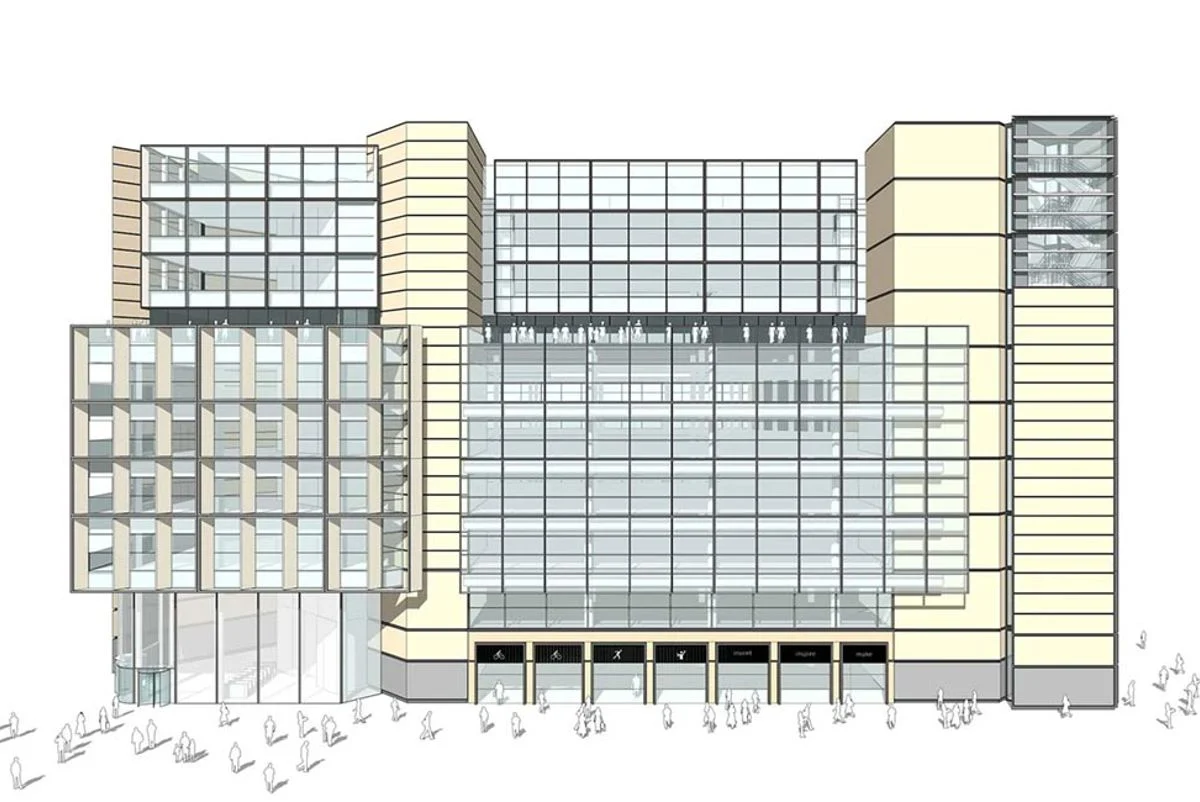

At Arup, we see this pivotal moment as an opportunity to challenge the status quo. The recently completed 1 Triton Square in London demonstrates that refurbishment can be exciting, attractive and incredibly sustainable, if the client is prepared to adopt a different mindset and champion a progressive strategy.

The project is an example of Arup’s marginal gains approach, with every system, component and strategy analysed and refined to maximise performance and deliver the most sustainable outcome – saving 40,000 tonnes of carbon and project completion being 30% faster compared to a typical new build.

Building retrofit and a 'marginal gains' approach

Arup originally designed 1 Triton Square for British Land in the 1990s. Twenty years later, customer needs evolved and British Land saw potential to increase the building’s size and transform it for today’s workstyles – opting for refurbishment to save time, money and carbon.

For Team Triton, comprising of client British Land, an all-Arup design team, and contractor Lend Lease, it became clear through the design process that there was an opportunity for an incredibly sustainable outcome. A “how much can we retain and reuse?” philosophy underpinned the team’s actions throughout the project.

The team chipped away at every aspect to save carbon, cut waste and deliver the best working environment possible. Through the marginal gains approach, they refined and optimised dozens of systems, components and strategies to deliver a highly sustainable building.

Circular economy principles in action

The project’s underlying philosophy of reuse aligns with Arup’s commitment to implement circular economy principles in our work.

Triton’s façade represents one of the largest examples of circular economy practices in the industry, requiring the removal, refurbishment and reinstallation of over 3,000m² of façade, comprising over 25,000 parts. This approach alone saved over 2,400 tonnes of carbon and represented a 66% cost saving when compared to a new façade.

Development Director, British Land

Creating an inviting and productive work space

1 Triton Square will become a healthy workplace for 3,500 people with exceptional amenity, and social connectivity. The atrium and new structure have been designed to incorporate satellite atria, floor to ceiling windows fill rooms with natural light, nearly 500m² of green roofs promote biodiversity, and five panoramic terraces provide space for socialising, working and relaxing.

Did you know?

-

Low carbon

1 Triton Square is now one of the lowest carbon HQs in the UK, with 40,000 tonnes of carbon saved compared to new build workplace - the equivalent carbon from the annual energy consumption of 9,900 average UK homes. It has been delivered 30% faster than a new build – with 6,000 fewer lorry journeys required by opting to refurbish the building.

-

Expansion

The reuse and strengthening strategies enabled three additional storeys to be added to the existing building, increasing the floor area by 70%

-

Capacity

It has secured the biggest pre-let in London’s West End in over 20 years.

-

Reuse

We reused as much of the existing structure and fabric as possible – 3,300m2 of limestone, 35,000 tonnes of concrete and 1,900 tonnes of steel. This accounts for 45% of the total carbon saving, the remainder of which stems from our marginal gains approach.

Projects

Explore more architecture projects:

Technical design advice to ensure the functionality and viability of Dubai's new super slender skyscraper

Muraba Veil, United Arab Emirates

Improving accessibility and user experience for tram stops in Melbourne

La Trobe Street Tram Stop Upgrades, Australia

Copenhagen's M4 metro line extension: five new stations to improve city connectivity

Copenhagen M4 metro line to Sydhavn and Valby, Denmark

A vital link from Bangkok’s city centre to the east

MRT Orange Line East Section, Thailand

Get in touch with us

If you'd like to speak to one of our Architecture experts about any of the issues raised on this page or a potential collaboration then please get in touch by completing the form.